Insertion Molding

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

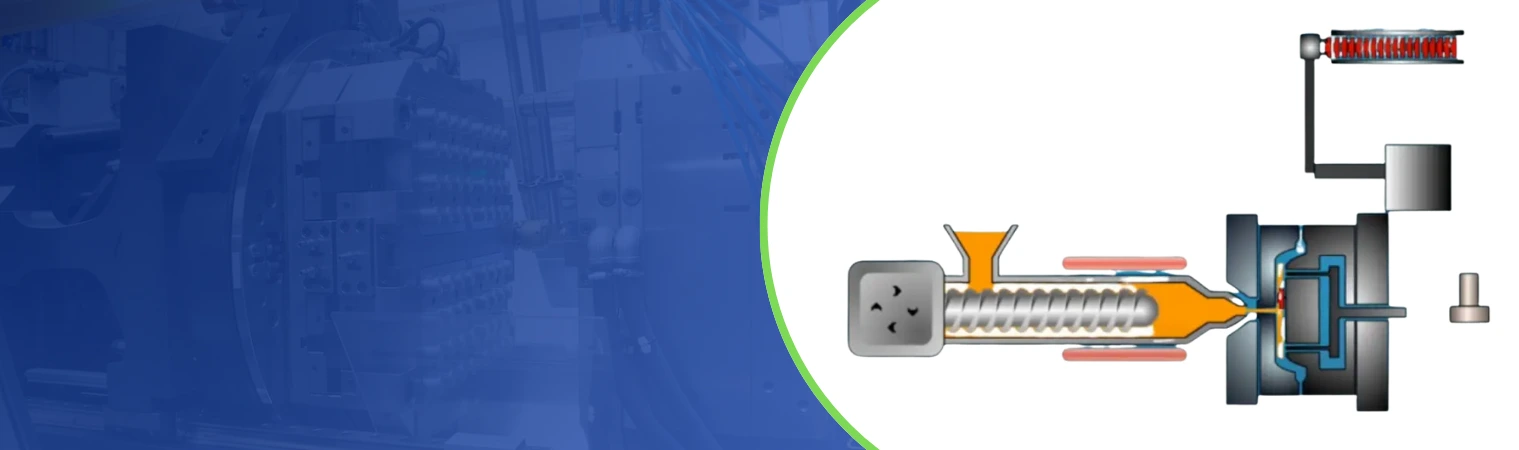

Insert molding is mainly defined as one industrial process, which will make proper use of the modern injection molding technology. This process has revamped the present day manufacturing help. The insert molding procedure will blend the metal and plastic or various other combinations of materials and components into one single unit. This insertion molding procedure will use the power of engineering plastic for enhancing that tensile strength and perfect weight reduction. It will also focus towards the wear resistance as well. Moreover, it can make use of the metallic materials for strength and conductivity.

It is true that you are focusing on the best molders near me and that’s when our name comes to the top of the list. We have been associated with this field for a very long time and can easily help you to make the right choice.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Mould Manufacturer In Industry

We will clearly focus on the importance and beauty of the molded precision components in here. Buy first, let’s check in with the advantages of the insert molding first.

Countries

Industries Served

Projects

Clients

You get the chance to reduce the labor cost, assembly and molded components cost with the insertion molding help. But for that, you need to choose our services to go for you.

Well, deposition modeling is one part of the molding section. Now, this method helps in increasing the reliability to the next level. Want to know how? If so, then make sure to join us for the best results.

So, if you have decided to get hands on the best thin wall molding, then make sure to join us for the help. You will receive quality responses from our side now. We will check in your needs first. Based on that, you can expect to get quality services from our side now.